Understanding the World of Bearings

Understanding the World of Bearings

Blog Article

Understanding the World of Bearings

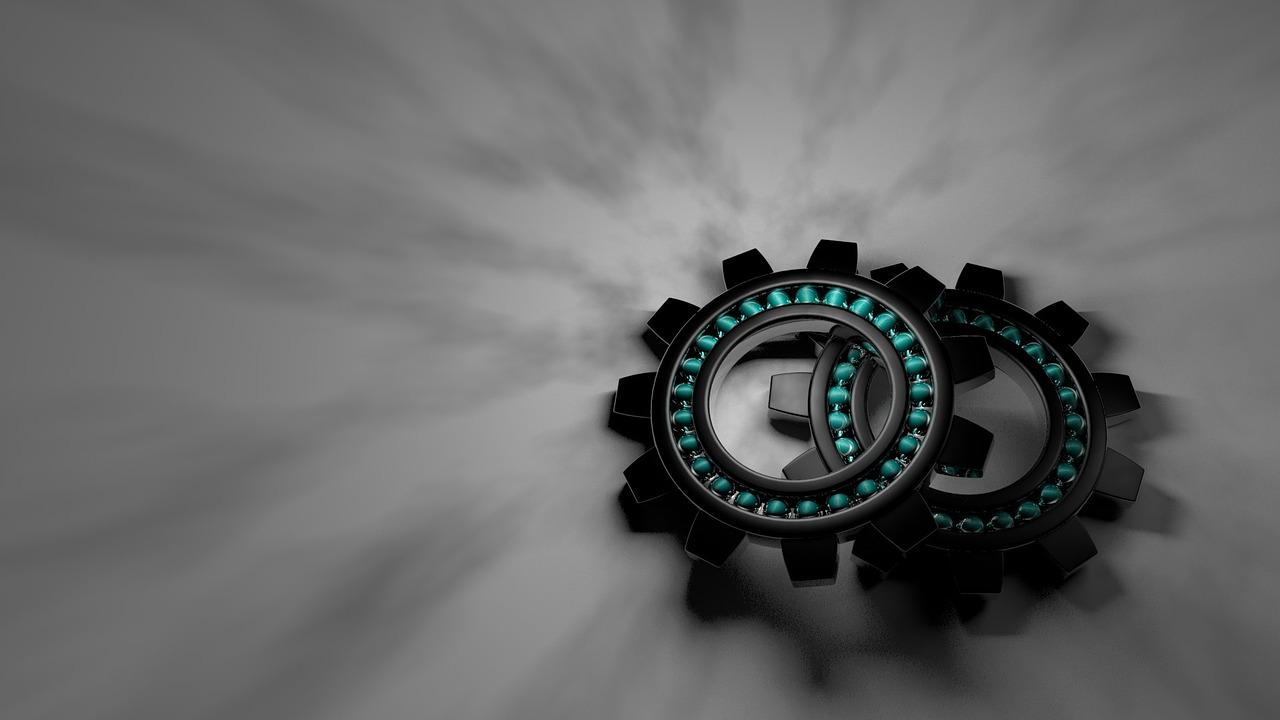

When delving into the intricate world of machinery and mechanical systems, bearings emerge as indispensable components that facilitate smooth and efficient operations. Bearings are pivotal in enabling the rotation or linear movement of various parts by reducing friction and supporting loads. The market offers a plethora of bearing types, each meticulously designed to cater to specific applications and operating conditions, showcasing the versatility and importance of these mechanical marvels.

Types of Bearings

Within the realm of bearings, a diverse array of options awaits, tailored to meet a spectrum of mechanical requirements. Among the most prevalent types are ball bearings, which leverage balls to copyright separation between the bearing races, ensuring optimal functionality. In contrast, roller bearings utilize cylindrical rollers to bolster heavy radial loads, showcasing their robust design and load-bearing capabilities.

For applications demanding the adept handling of both radial and thrust loads, tapered roller bearings or spherical roller bearings stand out as ideal choices. Tapered roller bearings excel in accommodating both load types within a single bearing, while spherical roller bearings exhibit prowess in managing misalignment and heavy loads concurrently, underscoring their versatility.

In specialized applications, needle roller bearings shine with their compact design and exceptional load-carrying capacity, catering to scenarios where space constraints are paramount. Additionally, thrust bearings carve a niche by providing dedicated support for axial loads, effectively curbing shaft deflection and ensuring operational stability.

Each bearing type boasts distinct characteristics that render it suitable for specific tasks, underscoring the importance of aligning the bearing choice with the machinery's unique requirements to optimize performance.

Trustworthy Bearing Factory

When embarking on the quest for bearings to fortify your equipment, entrusting a reputable bearing factory is paramount to securing high-quality products and dependable services. Esteemed entities like Tapered Roller Bearings Or Spherical Roller Bearings have cemented their standing by consistently delivering top-tier bearings that adhere to stringent industry standards.

These distinguished factories prioritize stringent quality control measures across the manufacturing spectrum, ensuring that their bearings epitomize durability, efficiency, and longevity. By opting for a reliable bearing supplier, you not only safeguard the seamless and reliable operation of your machinery but also instill confidence in the performance and longevity of your equipment.

Do You Need to Purchase Bearings?

Whether you helm a business seeking to copyright industrial equipment integrity or are a hobbyist engrossed in a DIY endeavor, recognizing the pivotal role of high-quality bearings is pivotal. Investing in superior bearings can catalyze enhanced performance and longevity for your machinery, culminating in substantial time and cost savings over the long haul.

Enterprises like Bearing Types You Should Know proffer an extensive array of bearings tailored to diverse needs and applications. Ranging from miniature bearings catering to precision instruments to heavy-duty counterparts servicing industrial machinery, reputable suppliers offer a comprehensive suite of solutions to address varied requirements.

Whether your bearings quest pertains to standard variants or necessitates bespoke solutions for unique applications, aligning with a dependable bearing factory emerges as the linchpin for project success. Remember, bearings stand as the unsung heroes of the mechanical realm, steadfastly supporting the seamless operation of myriad devices and machines. Opting for the right bearing type from a reputable supplier can wield a transformative impact on equipment performance and longevity, underscoring the critical role bearings play in the machinery ecosystem.

Report this page